Solving an 80" Problem

with asset55 Calculate

June 10, 2023

Overview

On the 31st of May 2023 a critical $2 Billion expansion project on a world-renowned refinery encountered problems. The key component holding progress was a bespoke 80” 300# joint on a Compressor Suction Drum Connection that failed a leak test. To solve this issue, asset55 was contacted.

Schedule

Due to this joint being on the critical path and was suddenly now delaying this project, a swift response was required. Without compromising on asset55’s strict engineering protocols, recommendations were issued in 48 hours to ensure this crucial phase of construction could continue.

Key objectives

The ASME standards (B16.5 and B16.47) only offer flange dimensions up to 60” so in depth analysis was required for this application due to the bespoke nature of the joint.

This required detailed review of the engineering drawings as well as the associated material properties to first identify any limitations of the joint and secondly recommend the correct bolt load for sealing this joint utilising asset55’s Calculate software.

Notable Outcomes

The analysis consisted of a review of both flanges, the gasket and bolts which were custom built due to the bespoke nature of the design.

There were also material considerations: this joint was designed for transporting liquefied natural gas (LNG) and hence required stainless steel components which were suitable for low temperature service, however also came with reduced strength. Thus, achieving a suitable gasket sealing stress was difficult without exceeding the flange strength and potentially damaging flanges, gaskets and bolts that could not be easily replaced or repaired.

The analysis completed by asset55 allowed the joint to be tightened correctly, effectively sealing the joint and allowed the project to get back on track.

Value creation

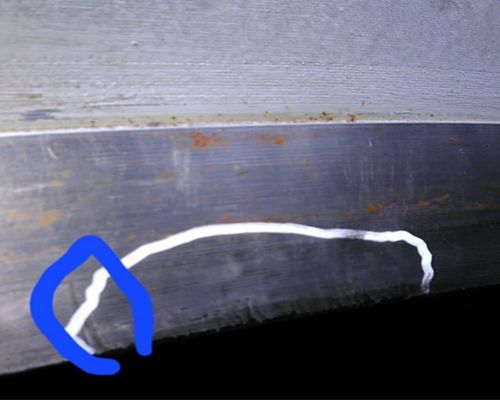

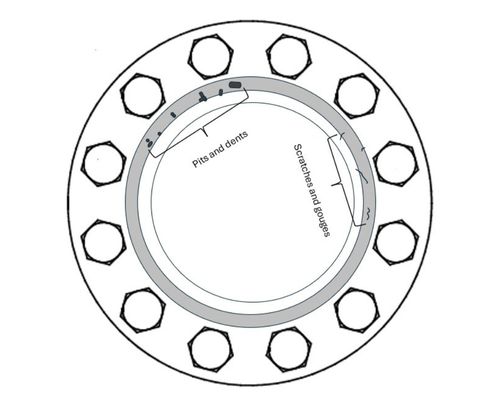

From asset55’s recommendations, this joint was successfully reassembled and sealed allowing the project to continue without serious interruption to schedule. As well as calculating the most appropriate bolt load based on the different bolt material options, asset55 also provided guidance on alignment and flange face specifications as per ASME PCC-1.

Flange face imperfections shown in the images taken from site, see ASME PCC-1 Appendix D for more detail.

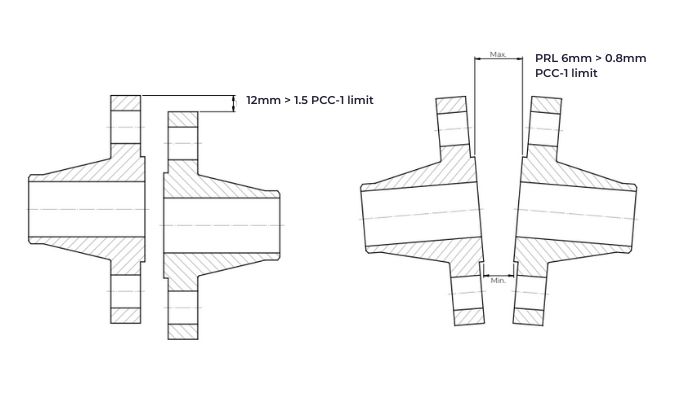

Images showing extreme misalignment from site of 12 mm. This misalignment was rectified as per asset55’s recommendations, by cutting the weld neck flange off and replacing with a new flange. See ASME PCC-1 Appendix E for more detail on misalignment parameters.

Calculate

Flawless start-up & operational excellence – the gold standard in flange management

Our industry leading bolt load calculator and flange management software, trusted by operators and contractors globally.